Junction Temperature Evaluation (II):

Three major factors affect the junction temperature of an LED: drive current, thermal path, and ambient temperature. With the optimum driving current, the amount of heat that needs to be removed depends upon superior heat sink designs to dissipate heat effectively.

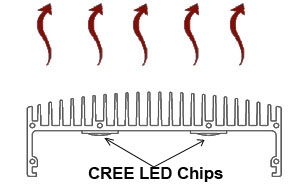

Our patent and proprietary heat fin design (see the figure at the right) maximizes the heat dissipation surface and minimizes the thermal path from the heat source. The pure aluminum heat sink material provides excellent thermal conductivity. The over all system is to ensure that the junction temperature to be kept as low as possible.

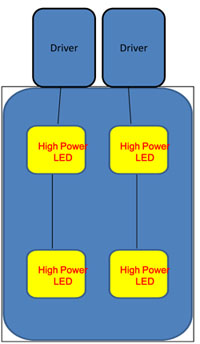

Our also patented modular power supply system, with power factor (PF) value 99%, is designed to efficiently provide the power to the LED circuit boards. One or more than one power suppliers can be used and be placed in a groove of the heat sink. (see the figure at the left) This fault-tolerant mechanism power system will allow each driver work independently and reliably. Besides, multiple drivers will lower the risks of light failure and ensure the long life of the LED light.

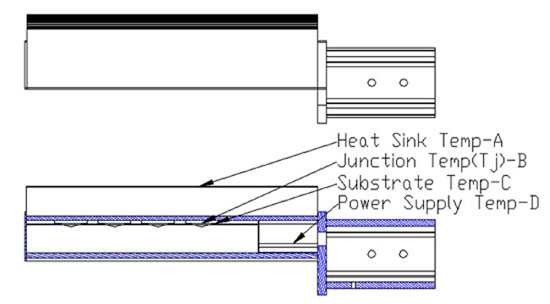

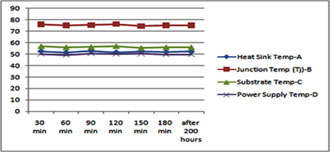

Two series of our street lights, S100(92W) and S150(145W) were tested for LED junction temperature evaluation. The setup is shown as the below. Three points temperature were measured throughout 200 hours testing : heat sink (temperature A), substrate (temperature C) and power supply (temperature D).

The junction temperatures were calculated based on the measured temperatures, thermal resistance between the LED and the solder point (9C/W) which is provided by CREE chip manufacture, forward voltage across LEDs and forward current of 650 mA supplied to the LED. (See the charted data below)

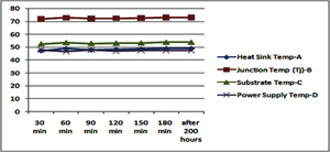

S100 (92W)S150 (145W)

The data shows that the junction temperature stabilized about 45 minutes of operation at 25C room temperature and stayed constant throughout the entire 200 hours testing . The average junction temperature, ranged between 70C to 75C corresponds to a minimum of 90% relative luminous flux output and up to 100,000 hours of useful life.

Our products have been certified by all industry standards and also been installed and tested world wide under severe climates like high wind typhoons, dry & hot deserts, icy snows, etc. since the introduction four years ago. Products are still effectively lighting streets, roadways and highways regardless of the weather patterns. A street light life test conducted in Germany shows no lumen depreciation after one and a half years which encourages a long useful life expectation.

847-683-8002 Fax 847-683-8001 120 Rowell Road, Hampshire, IL 60140 sales@ledrite.com